CIP Cleaning in the Food Industry: The “Secrets” You Never Knew!

Category: Corporate News

Published Time: 2024-04-10

Summary: In the production processes of food processing enterprises (including dairy, beverages, beer, meat products, etc.), the cleaning of processing equipment and pipelines is of critical importance.

For food processing enterprises (including dairy, beverages, beer, meat products, etc.), the cleaning of processing equipment and pipelines is crucial during the product production process. After use, processing equipment and pipelines tend to accumulate impurities, dirt (such as fats, proteins, sugars, high-temperature carbonized substances, etc.) and bacteria. Professional cleaning agents must be used to ensure product quality and safety.

In the early days, most food enterprises chose to use industrial sodium hydroxide and nitric acid for equipment and pipeline cleaning. This method had poor cleaning efficacy, would cause heavy metal contamination, leave residual dirt and bacteria, and could even lead to secondary pollution.

Therefore, food processing enterprises must thoroughly clean and sanitize their equipment and pipelines using food-grade cleaning agents that meet QS requirements after production is completed. This prevents microbial proliferation and ensures product sanitation quality.

Comparison Table of Current Cleaning Practices in the Food Industry

| Industrial acids and alkalis | Food additive acids and alkalis | Professional compound acids and alkalis | |

| Cleaning effect | ★★★ | ★★★ | ★★★★★ |

| Safety factor | ★★ | ★★★★★ | ★★★★★ |

| Usage status | 30% | 25% | 45% |

Food additive acid-base agents: while safe for use, their lack of specificity results in inadequate cleaning efficacy and elevated operational costs.

Industrial acids and alkalis: relatively low cost, but poor cleaning effectiveness. Most importantly, they lead to excessive heavy metals, residual bacteria, and lack safety assurance.

Professional composite acid and alkali cleaning agents: comply with the QS requirements, highly efficient and safe, with a high cost-performance ratio. They offer high cleaning efficiency and save on usage while ensuring safety.

The distinction between composite acid-base cleaning agents and single-component cleaning agents.

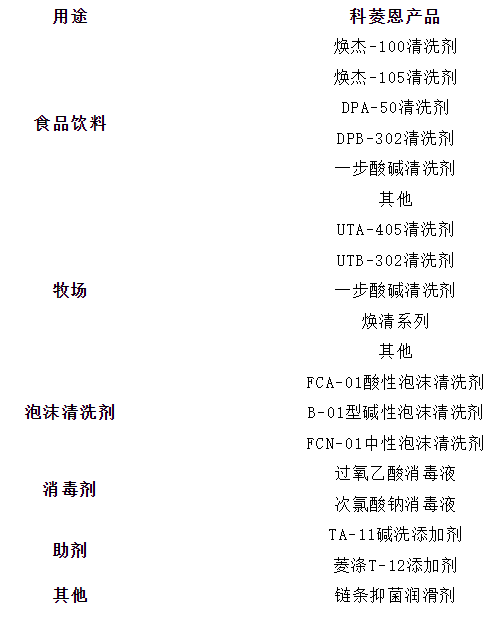

Klean Biotech has long been committed to developing and producing composite acid-alkali cleaning agents for food equipment. So what exactly are the differences between these composite acid-alkali cleaners and single-component cleaning agents?

01 Cleaning effect

Composite acid and alkali cleaning agents incorporate chelating agents, surfactants, and cleaning aids during processing, which ensures good cleaning effects and allows for the removal of residual dirt on equipment within a short period of time. In contrast, single-type cleaning agents (generally refers to a single sodium hydroxide and nitric acid) have poor cleaning efficiency, weak penetration power, and fail to provide thorough cleaning.

02 Security coefficient

Composite acid and alkali cleaning agents have more controllable content of active substances, and they are supplemented with other additives and corrosion inhibitors, which makes them relatively safer for humans and less corrosive to equipment and seals. Single-type cleaning agents (generally refers to a single sodium hydroxide and nitric acid) are highly corrosive, extremely unsafe for humans, and highly corrosive to equipment and seals.

03 Food safety

Composite acid and alkali cleaning agents are much easier to rinse. They not only have a high cleaning efficiency but also leave no residue. Single-type cleaning agents (usually referring to sodium hydroxide and nitric acid alone) have low cleaning efficiency, are not easy to rinse off, and can even cause secondary pollution.

04 Environmental protection aspect

Composite acid and alkali cleaning agents have a low wastewater treatment load. Single-type cleaning agents (usually referring to sodium hydroxide and nitric acid alone) have a high wastewater treatment load. Industrial acids and alkalis often contain excessive heavy metals, which increase the difficulty and load of wastewater treatment.

Keywords: CIP Cleaning in the Food Industry: The “Secrets” You Never Knew!

Related News

Corporate News

-

Klean Empowerment Bootcamp | Three Days of Intensive Training: Unlocking Advanced Strategies in Management and Sales

Time:2025-06-07

-

University-Enterprise Synergy Cultivates Elite Talents | Klean and Northwestern Polytechnical University jointly established employment and internship base

Time:2025-04-27

-

The cornerstone of food safety – Cleanliness is the lifeline of the food industry

Time:2024-08-01

-

Corrosion Behavior and Preventive Measures of Metal Equipment During Cleaning Operations

Time:2024-05-17

-

CIP Cleaning in the Food Industry: The “Secrets” You Never Knew!

Time:2024-04-10

-

How to properly use disinfectants

Time:2025-05-12

-

How to properly store alkaline and acidic cleaning agents?

Time:2025-05-12

-

What are the usage methods and precautions for alkaline cleaning agents?

Time:2025-05-12

-

How to properly use acidic cleaning agents to avoid danger?

Time:2025-05-12

-

Application scenarios of acidic cleaning agents

Time:2025-05-12

Industry Trends

-

The State Administration for Market Regulation (SAMR) has introduced 37 key measures to support the development of private enterprises.

Time:2025-04-17

-

Green consumption new fashion: Master Kong's low-carbon products debut at Shanghai Carbon Expo

Time:2025-06-17

-

From Guizhou to the world - Ciningji C+ makes its debut at the Guizhou prickly pear industry event

Time:2025-06-17

-

Four departments jointly issue agricultural disaster prevention and mitigation plan for flood season, striving for a bumper harvest of grain and agriculture

Time:2025-05-13

-

Warmly welcome! The Dairy Industry Conference, D20 Forum, and Exhibition will be held in Xiamen from July 13-15.

Time:2025-05-27

-

What is the difference between alkaline and acidic cleaning agents?

Time:2025-05-12

-

What are the applications of alkaline cleaning agents?

Time:2025-05-12

-

Which metal materials cannot be cleaned with acidic cleaning agents?

Time:2025-05-12

-

How should I handle an acid cleaning agent spill on my skin?

Time:2025-05-12

-

How corrosive are acidic cleaners?

Time:2025-05-12

陕公网安备61042202000152号

陕公网安备61042202000152号